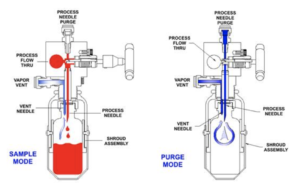

Manual Continuous Sampler Systems

Texas Sampling’s Manual Continuous sample system is a closed loop liquid sampler that satisfies many sampling needs. This system will take emission free, representative samples of process while providing operator safety. Our patented valve design ensures zero dead volume throughout the sample valve assembly. Easy to install and operate, process pressure is used to dispense the sample into the sample bottle.